OFFSHORE SUPPORT VESSELS

85M Offshore Support Vessel (OSV-DP2) + more information

Tehuana

85M Offshore Support Vessel (OSV-DP2)VERSATILITY

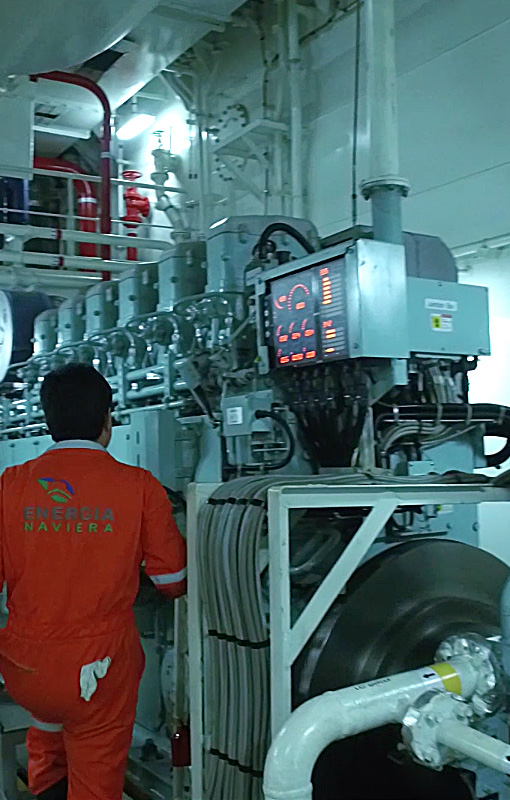

Our vessels have Dynamic Positioning Class 2 making them the most main machine of its type, reaching a speed of 12.5 knots, has two main machines of 3,000 HP, in combination with its two bow thrusters type tunnel, has a fast and efficient maneuverability, entering into confined spaces where other vessels are not able to achieve.

On the main deck towards stern starboard strip, the vessels have a modern MacGregor crane, with a SWL of 100 Tons. Strategically located, allowing to perform any activity easily.

Due to be last generation vessels constructed in 2014 & 2015, the consumption of diesel is low, being this, an important factor that allow savings during the operation.

FIGHT FIRE SYSTEMS (FIFI)

Each of our vessels has two horizontal centrifugal type FiFi fire pumps coupled to a kumera brand speed elevator and this in turn is coupled to each main machine.

Its discharge capacity is 2,200 m³/hr at a distance of 130mts at 1,800 RPM.

HELIPORT

The heliport has the proper certification and the most modern equipment for the intercommunication with flights, radio equipment and monitoring of last generation that provide the greater security and reliability for the operation.

The helideck has 9.3 tons capacity, able to receive Sikorsky helicopters at any day or night time.

LODGING CAPACITY IN HOUSING AREA

The boats have cabins for 200 people including the crew, distributed in 5 housing decks.

Level 1: this area has the area of gambuza, cold rooms of meats and vegetables, a pantry, kitchen, main dining room, recreation room, internet room, office area, laundry, general restrooms and hospital.

Level 2: Engineering Offices and cabins with their respective individual bathrooms.

Level 3, 4 and 5: Staterooms with their respective individual bathrooms.

The bridge deck has a waiting room and a radio station for the heliport.

MOON POOL

Each boat has areas for saturation diving located at the center of the boat, with square dimensions at of 8.20 meters x 8.20 meters.

SLUDGE TANK

Each vessel has 6 sludge tanks, 3 to each side of the boat, with total capacity per boat of 410 m3 with independent agitator each tank.

TANK OF VARIT AND CEMENT IN BULK

It has 4 silos of 2,000 Ft³ each, making a total capacity of 226 m³ and a discharge system commanded by solenoid valves and pneumatic system of air compressors and dryers.

WATER MARKERS

Each boat has 2 water markers, with capacity of 30 tons each every 24 hours.

Its treatment is a Reverse Osmosis Type. The plants discharge the production to 6 storage tanks. The capacity of storage of water produced per boat is 740 m3.

WASTE WATER TREATMENT PLANT (WWTP)

This WWTP plant has capacity for 200 people and treats wastewater for 3 stages.

Stage 1 receiving in the buffer tank.

Stage 2 Biochemical treatment membranes (biological bacteria) in parallel with the air compressor.

Stage 3 Ultraviolet (UV) filter to sterilize the water to eliminate micro-organisms in suspension.

Finally, clean outboard water is discharged, according to regulations governig IMO.